Introduction to Industrial Heating Elements

Industrial heating elements are critical components in many industrial applications. From high-precision temperature control in laboratories to large-scale manufacturing operations, they are indispensable for achieving optimal performance in processes such as metal forging, ceramic production, and glass manufacturing. This Industrial Heating Element Selection Guide will provide a comprehensive look at the different types of heating elements, their applications, and how to choose the right one for your needs.

Types of Industrial Heating Elements

Understanding the different types of heating elements is crucial in selecting the right one for your industrial process. Below, we highlight the most common types of heating elements and their unique benefits.

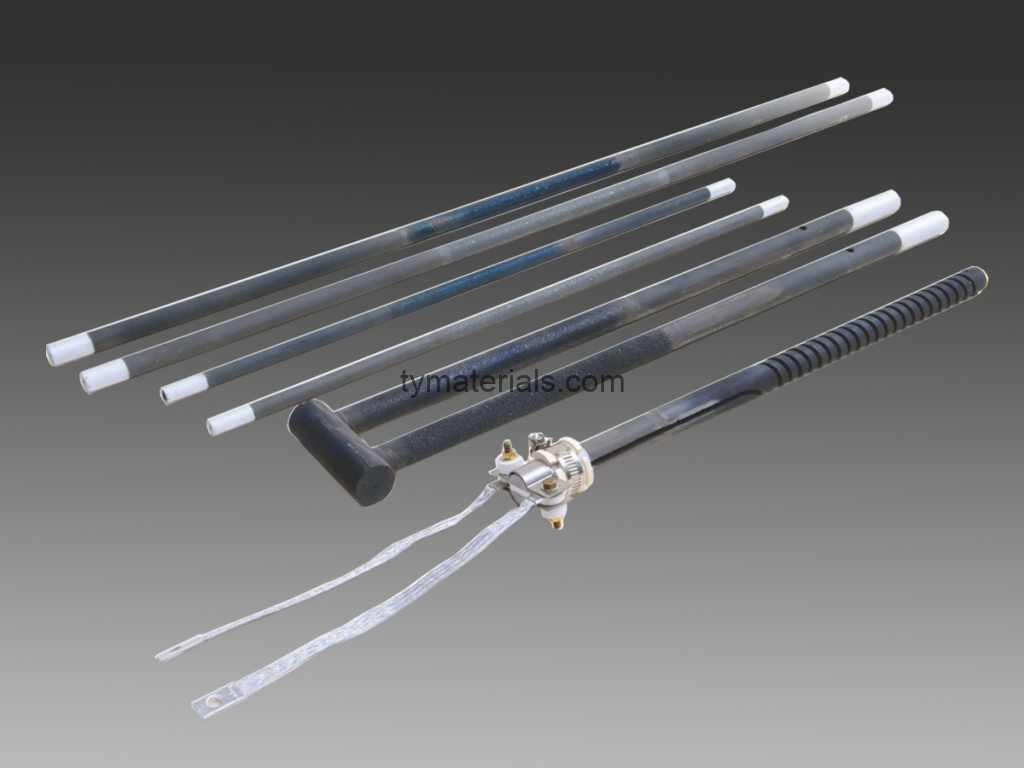

Silicon Carbide Heating Elements

Silicon Carbide Heating Elements are known for their outstanding high-temperature resistance and durability. They are ideal for environments that require long-lasting performance under extreme conditions. Silicon Carbide heating elements are commonly used in applications like kilns and furnaces. These heating elements offer excellent thermal conductivity and oxidation resistance, making them perfect for industries such as ceramics, metal processing, and glass manufacturing.

Discover more about the Silicon Carbide Heating Elements we offer in our Industrial Heating Element Selection Guide.

Metallic Heating Elements

Metallic Heating Elements are known for their fast heating capabilities and energy efficiency. They are often used in electric ovens, dryers, and heating systems. These elements are made from conductive metals such as copper, aluminum, and iron, and they deliver consistent heat quickly. Metallic heating elements are also preferred for their cost-effectiveness and versatility across various industrial applications.

Check out our range of Metallic Heating Elements in our Industrial Heating Element Selection Guide.

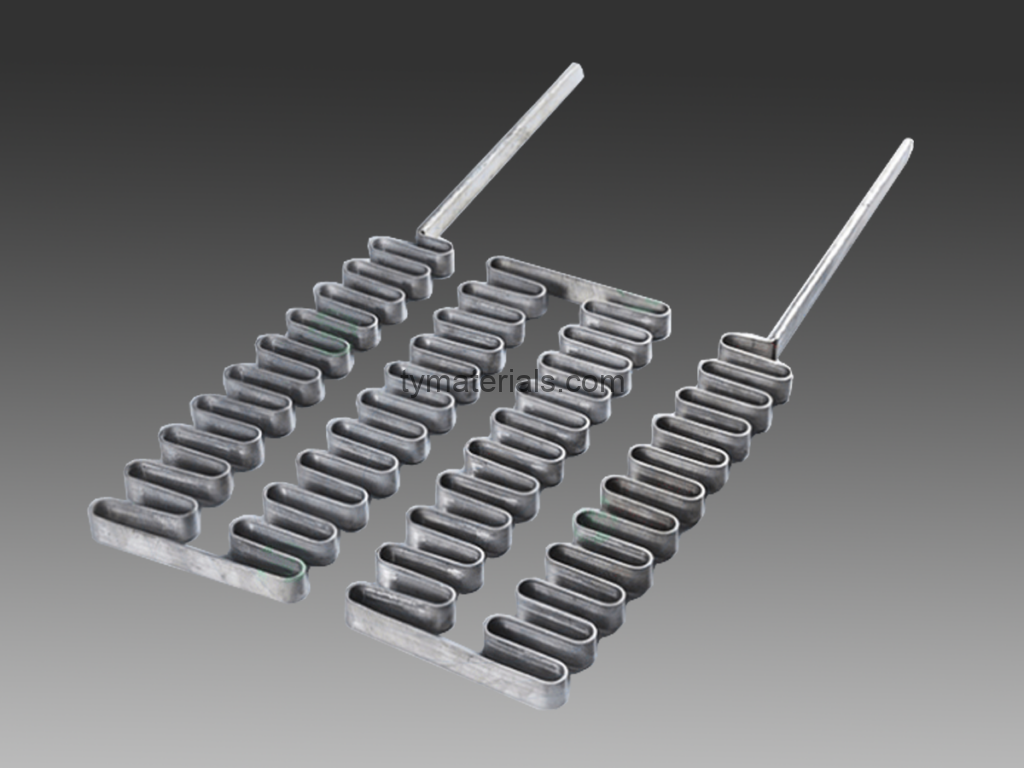

Molybdenum Disilicide Heating Elements

Molybdenum Disilicide Heating Elements are designed to withstand extreme temperatures, making them ideal for high-temperature furnaces and kilns that reach over 2000°C. These elements are perfect for industries requiring high oxidation resistance and long-term durability. Molybdenum Disilicide heating elements are especially useful in the glass manufacturing industry, where intense and continuous heating is required.

Learn more about the Molybdenum Disilicide Heating Elements and their applications in our Industrial Heating Element Selection Guide.

Applications of Industrial Heating Elements

Industrial heating elements have a broad range of applications across various sectors:

- Metal Processing: Heating elements are vital in heat treatment, casting, and smelting operations. They help in maintaining precise temperatures for metal processing and are used in industries like aerospace, automotive, and manufacturing.

- Glass Manufacturing: Used for melting, molding, and annealing processes. Molybdenum Disilicide Heating Elements are particularly effective in glass manufacturing due to their ability to handle extremely high temperatures.

- Ceramics Production: Silicon Carbide Heating Elements are key to firing ceramics in high-temperature kilns and furnaces.

- Research and Laboratories: For experiments that require precise temperature control, such as material testing and chemical analysis.

How to Select the Right Heating Element

Selecting the right heating element for your application can be tricky. Here are some key considerations:

- Temperature Requirements: Determine the maximum temperature needed for your application. If temperatures exceed 2000°C, Molybdenum Disilicide Heating Elements are ideal.

- Material Compatibility: Ensure that the heating element material is compatible with the materials you are heating. For example, Silicon Carbide Heating Elements are excellent for ceramics and glass, but may not be suitable for all metal types.

- Energy Efficiency: Look for heating elements that are energy-efficient to lower operating costs. Metallic Heating Elements are often chosen for their cost-effectiveness and fast heat-up times.

- Size and Shape: Heating elements can be customized in various shapes, such as spiral, U-shaped, and straight rods, to fit your equipment’s design.

Visit our Product Selection Guide to choose the best heating element for your needs.

Key Benefits of Industrial Heating Elements

The benefits of industrial heating elements are numerous and include:

- Durability: Heating elements like Silicon Carbide and Molybdenum Disilicide can withstand extreme temperatures without degrading, providing long-term reliability.

- Energy Efficiency: Many heating elements, including Metallic Heating Elements, are designed to maximize energy usage, which helps in reducing operational costs.

- Versatility: Heating elements can be used in a wide variety of applications, from ceramics production to metal processing and glass manufacturing.

Conclusion

Choosing the right industrial heating element is crucial to achieving optimal performance in your operations. With the variety of options available, understanding the different types of heating elements and their specific applications will help you make an informed decision. For further assistance, visit our Contact Us page for personalized recommendations and guidance.

Industry Applications and Case Studies

Silicon Carbide Heating Elements are widely used in the metal processing industry for heat treatment processes. Their high resistance to thermal shock makes them ideal for use in heat treatment furnaces, helping manufacturers achieve precise control over their processes.

In the glass industry, Molybdenum Disilicide Heating Elements are used in high-temperature furnaces. Their ability to operate at over 2000°C is essential for glass melting, allowing for efficient and reliable production of high-quality glass.

Common Questions about Industrial Heating Elements

What is the best heating element for high-temperature applications? If your application involves extreme temperatures above 2000°C, Molybdenum Disilicide Heating Elements are the ideal choice. They are designed to withstand these temperatures and offer excellent oxidation resistance.

Can heating elements be customized for specific needs? Yes, our heating elements can be customized in terms of size, shape, and power output to meet your specific requirements. Visit our Products Page for more options.

Outbound Links and Industry Resources

To stay updated on industry standards and innovations in heating element technology, we recommend checking the following resources:

- The Association for Manufacturing Technology

- Science Direct – Heating Element Materials

- ISO – Industrial Heating Equipment Standards

Call to Action

Ready to enhance your industrial heating process? Explore our Product Selection Guide or Contact us for expert consultation.