Heat treatment furnaces play a crucial role in the manufacturing and processing industries. These furnaces are used to treat materials such as metals, ceramics, and alloys by applying heat, often in controlled atmospheres, to alter their physical and chemical properties. The quality of the heating elements used in these furnaces directly impacts the furnace’s efficiency and the precision of the heat treatment process. In this article, we’ll explore the different types of heating elements, their role in heat treatment furnaces, and how TY Materials Co., Ltd. can provide the right solutions for your needs.

What is a Heat Treatment Furnace?

A heat treatment furnace is a specialized industrial furnace used to heat materials to a specific temperature and hold them at that temperature for a prescribed amount of time. To better understand the types of materials used in high-temperature applications, you can explore our article on Understanding Refractories: Essential Materials for High-Temperature Applications, which explains the importance of refractories in furnace operations. The main goal of the process is to enhance the material properties, such as hardness, ductility, or resistance to wear. Heat treatment is widely used in industries such as automotive, aerospace, electronics, and metalworking.

The Role of Industrial Heating Elements

The efficiency of a heat treatment furnace heavily depends on the type of industrial heating elements used. These elements are responsible for converting electrical energy into heat and distributing it evenly throughout the furnace chamber. For a broader understanding of heating elements used in various industrial applications, visit our Industrial Heating Elements Guide. The quality and design of these elements can influence the furnace’s temperature uniformity, energy consumption, and longevity.

Types of Heating Elements in Heat Treatment Furnaces

At TY Materials Co., Ltd., we specialize in a variety of industrial heating elements designed for high-performance applications in heat treatment furnaces. Some of the key products include:

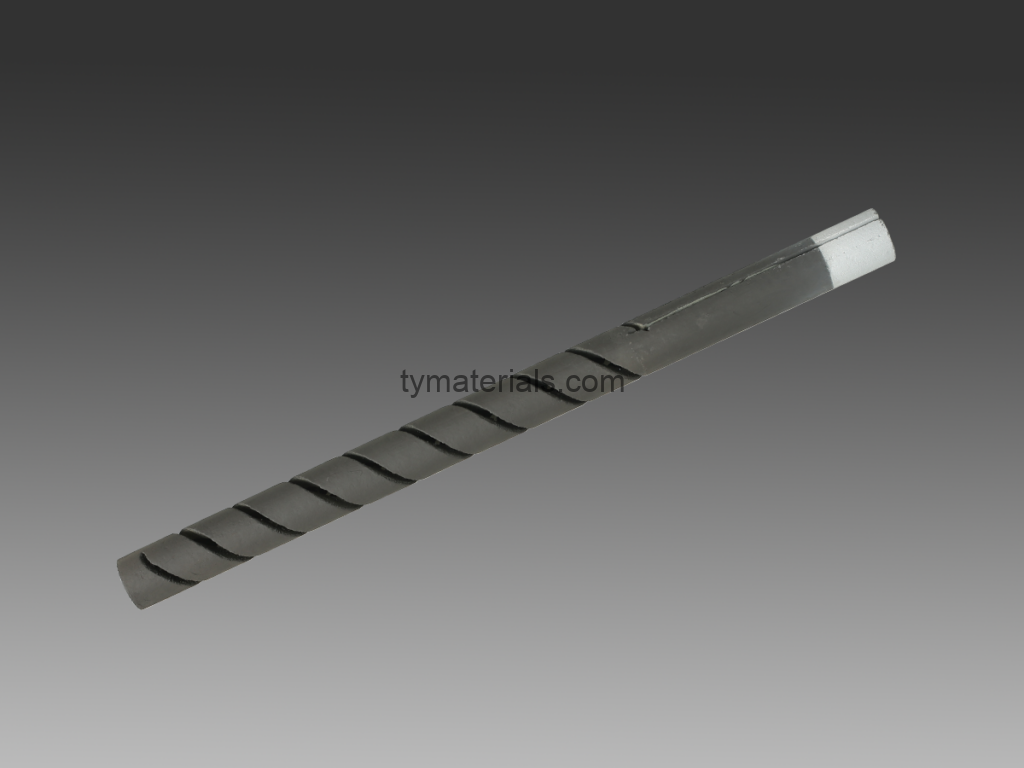

Silicon Carbide Heating Elements

Known for their high thermal stability and resistance to oxidation, Silicon Carbide Heating Elements are ideal for high-temperature applications in furnaces. For instance, our Double Spiral Silicon Carbide Heating Element is designed to ensure even heat distribution and long-lasting performance in demanding environments. You can also learn more about Silicon Carbide’s role in metal melting by visiting our Aluminum Melting Pot: Essential for Efficient Metal Casting page.

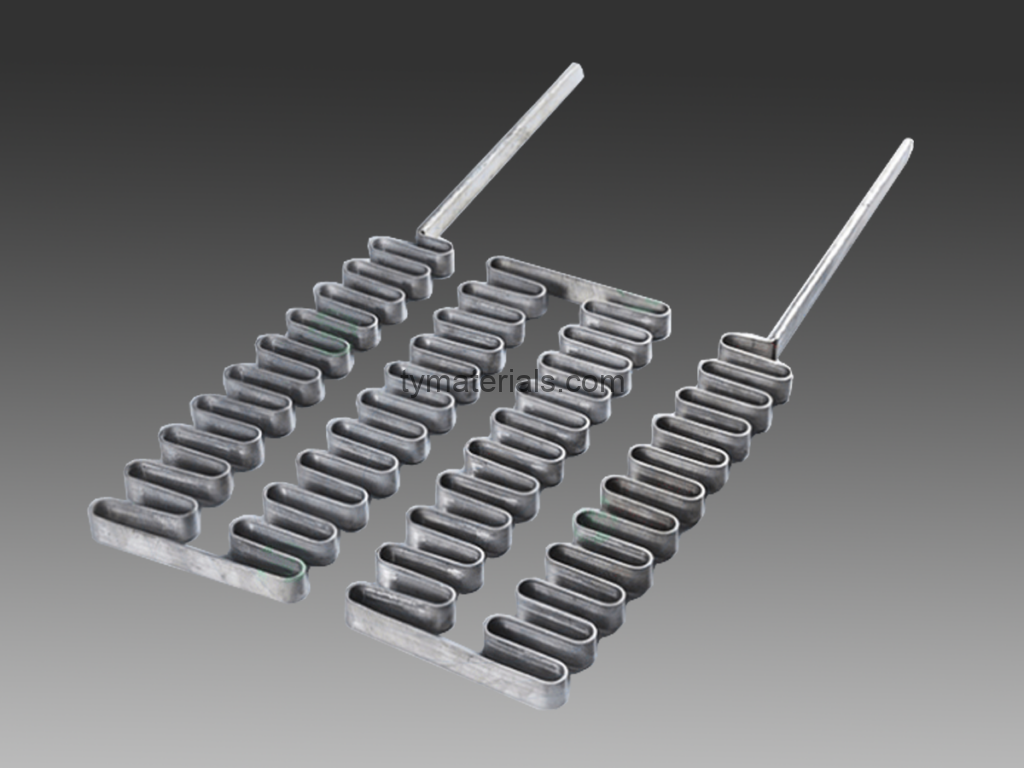

Molybdenum Disilicide Heating Elements

These elements are often used in furnaces that require temperatures above 1500°C. Molybdenum Disilicide provides excellent durability and resistance to high temperatures, making it suitable for processes like heat treating alloys and ceramics. Learn more about this product on our Molybdenum Disilicide Heating Element page.

Metallic Heating Elements

For more cost-effective solutions, Metallic Heating Elements are used in furnaces that do not require the extreme temperatures that Silicon Carbide or Molybdenum Disilicide can withstand. These elements provide reliable and efficient heating for a range of industrial applications.

How to Choose the Right Heating Element for Your Furnace

Selecting the right heating element is critical to ensuring your heat treatment furnace performs optimally. Factors such as maximum operating temperature, thermal conductivity, and resistance to corrosion should be considered. To better understand the properties of different heating elements, check out our article on Understanding Resistance Heating: How It Works and Its Applications. At TY Materials, we offer a variety of products that can be customized to meet the unique requirements of your heat treatment processes. For a detailed overview of our heating elements, visit our Industrial Heating Elements page.

If you’re looking for advanced solutions, our Silicon Carbide Radiant Tubes might be the perfect fit. These tubes offer superior resistance to thermal shock and are commonly used in high-temperature heat treatment furnaces. You can explore more about these tubes on our Silicon Carbide Radiant Tube page.

Benefits of Using High-Temperature Ceramics in Heat Treatment Furnaces

In addition to heating elements, High-Temperature Ceramics play an essential role in enhancing the performance of heat treatment furnaces. Materials like Silicon Carbide Crucibles and Alumina Ceramic Rollers are designed to withstand extreme temperatures while maintaining structural integrity.For more details on high-temperature ceramics, visit our High-Temperature Ceramics page. These ceramics are crucial for applications such as metal casting and sintering processes. You can find more information about these ceramics on our High-Temperature Ceramics page.

Industry Trends and Insights

The heat treatment industry continues to evolve with new advancements in materials and technologies. According to recent trends in the field of heat treatment and refractory materials, there has been a significant push toward more energy-efficient solutions and sustainable practices. As these trends evolve, industry players need to stay updated on the latest developments to remain competitive. A good resource for staying informed about these trends is the Refractories World Forum, an industry publication that provides in-depth articles and news related to refractories and heat treatment.

Get in Touch with TY Materials Co., Ltd.

Are you ready to enhance the performance of your heat treatment furnace with high-quality heating elements? TY Materials Co., Ltd. offers a wide range of products that meet the highest standards of durability and efficiency. If you have any questions or need more information, we invite you to contact us today.

Additionally, if you’re looking for a tailored solution, feel free to get a quote from us. Our team will be happy to assist you with your specific requirements.

Conclusion

A heat treatment furnace is an essential piece of equipment in many industries, and the quality of its heating elements significantly impacts its performance. By choosing the right industrial heating elements and ceramics, such as those offered by TY Materials Co., Ltd., you can ensure efficient, reliable, and high-quality heat treatment processes.For more information on heat treatment furnace components, explore our Ceramic Fiber Insulation and Fire Bricks articles, which dive deeper into the insulation materials that complement heating systems. Whether you need Silicon Carbide Heating Elements or Molybdenum Disilicide Heating Elements, we provide the right products to meet your needs. Explore our full range of products and solutions for heat treatment furnaces today.

Contact Us for More Information:

If you’re looking for expert advice on selecting the best heating elements for your heat treatment furnace or need a custom quote, don’t hesitate to reach out. Our contact form is available for you to fill out, and our team will get back to you promptly with the best solutions for your requirements.