For industries that operate under extreme heat, ceramic insulation has become a game-changer. Lightweight, durable, and highly efficient, ceramic fiber insulation is widely used in furnaces, kilns, and reactors, where maintaining consistent thermal performance is critical. This innovative material—also known as insulating ceramic—offers exceptional thermal resistance and energy-saving properties.

Understanding Ceramic Insulation Materials

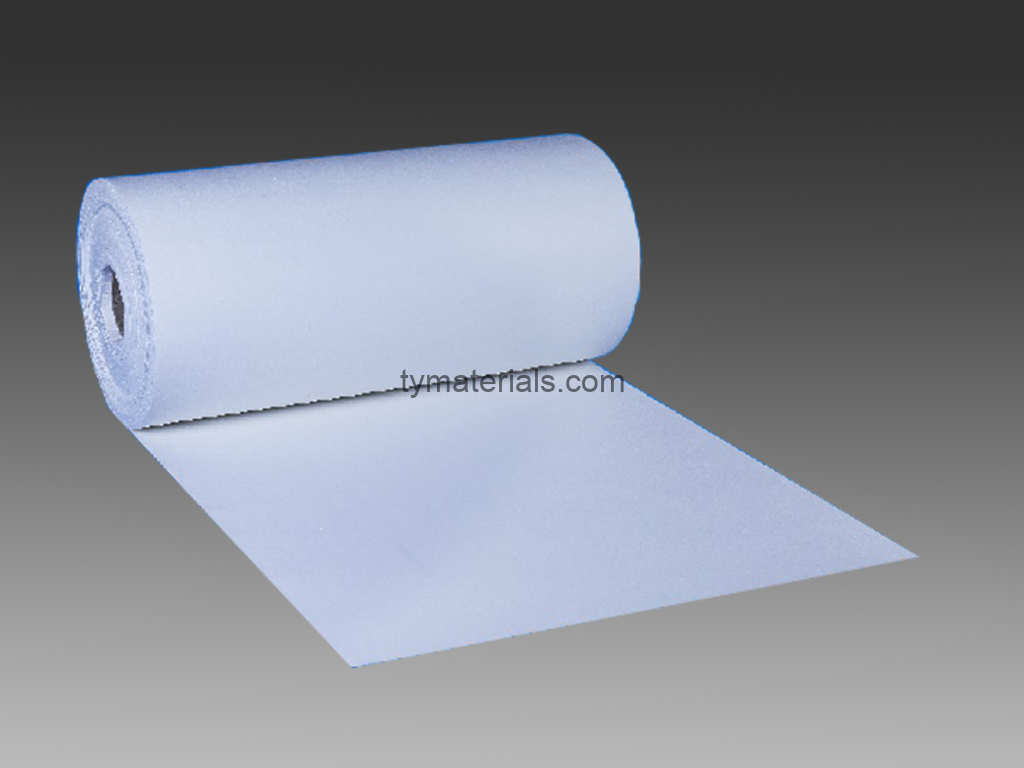

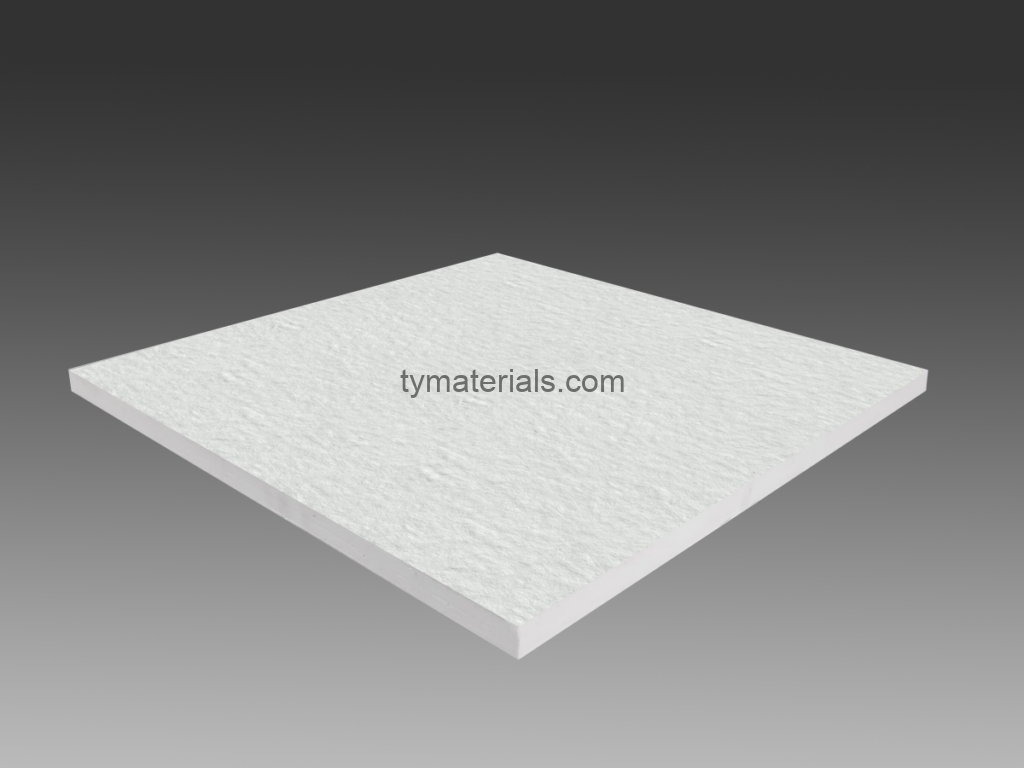

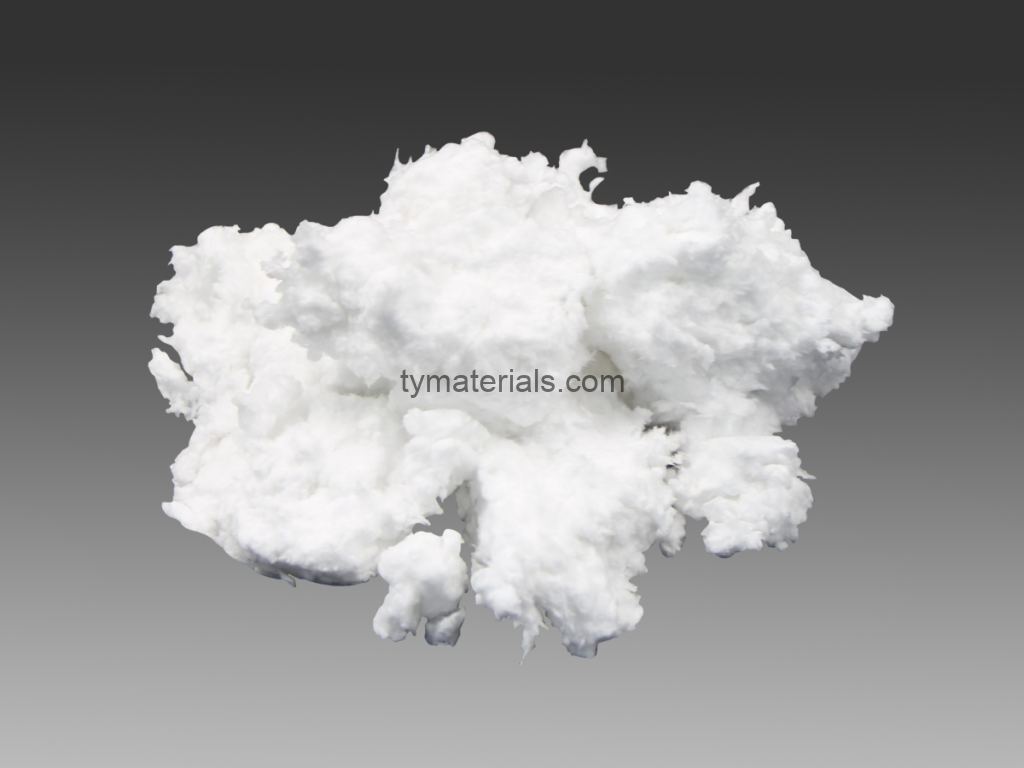

Ceramic fiber insulation is a high-performance solution designed to withstand extreme temperatures while minimizing energy loss. Made from spun ceramic fibers, it is available in various forms such as ceramic blankets, boards, and tapes. These versatile materials adapt to a wide range of industrial needs, providing both flexibility and durability.

Advantages of Insulating Ceramic Solutions

- Superior Heat Resistance

Materials like ceramic insulation blankets are designed to perform under temperatures exceeding 1,200°C (2,192°F), making them essential in high-temperature environments. - Energy Efficiency

By reducing heat transfer, products such as ceramic wool insulation help lower energy costs, improving the overall efficiency of industrial systems. - Lightweight and Easy to Install

Unlike traditional insulating materials, insulation ceramic is both lightweight and adaptable, allowing for seamless application in complex systems. - Durability Under Harsh Conditions

Resistant to wear and chemical degradation, ceramic fiber products ensure long-term performance in demanding industrial settings.

Practical Applications of Thermal Insulation Ceramics

Industrial operations depend on ceramic insulation materials to maintain efficiency and safety in high-heat environments. Some common applications include:

- Furnace Linings

High-performance ceramic fiber blankets and boards are commonly used to line furnaces and kilns, reducing energy loss and maintaining consistent temperatures. - Seals and Gaskets

Heat-resistant seals made from ceramic tapes and ropes are critical for preventing heat and gas leaks in industrial equipment. - Metal Processing

Foundries rely on ceramic wool insulation and fireproof blankets to stabilize temperatures during metal casting processes.

To learn more about our tailored insulation products, visit our Ceramic Fiber Products page. Explore our wide range of high-performance solutions, including Ceramic Fiber Blanket, Ceramic Fiber Module, Ceramic Fiber Board, Ceramic Fiber Paper, Ceramic Fiber Wool, and Ceramic Fiber Yarn. Each product is designed to meet the unique demands of high-temperature industrial applications, combining durability, energy efficiency, and adaptability. Below are some highlights of our product offerings:

Learn more about Ceramic Fiber Blanket

Discover Ceramic Fiber Module

View Ceramic Fiber Paper Details

Explore Ceramic Fiber Board

Learn more about Ceramic Fiber Wool

Discover Ceramic Fiber Yarn Applications

How to Choose the Right Ceramic Insulation Product?

Selecting the right ceramic insulation solution depends on your specific needs:

- For High-Heat Applications: Use ceramic fiber boards, which provide superior resistance to extreme temperatures.

- When Flexibility is Key: Opt for ceramic blankets or ceramic wool insulation, which offer adaptability in challenging installations.

- For Structural Integrity: Consider insulating ceramic boards, which combine strength with thermal efficiency.

Discover complementary solutions like our Refractory Bricks, designed to enhance heat resistance in high-temperature systems.

Trends in Energy-Efficient Insulation Materials

The demand for sustainable and efficient materials is driving innovation in thermal insulation ceramics. By adopting advanced solutions like ceramic fiber insulation, industries are reducing operational costs and lowering their environmental impact.

For more insights into ceramic and refractory innovations, visit Refractories World Forum, a leading resource for industry updates.

Contact Us for Tailored Ceramic Insulation Solutions

At TY Materials, we specialize in high-performance ceramic insulation products that meet the unique demands of your industry. Whether you’re looking for ceramic blankets, fiber boards, or custom solutions, our team is ready to assist.

Contact us today! Complete the form below for a personalized quote or detailed recommendations: