Introduction to Kiln Heating Elements

Kiln heating elements are essential components in many industrial applications, providing the necessary heat for processes such as metal melting, ceramics firing, glass production, and heat treatment. These elements need to be durable, efficient, and capable of operating at high temperatures. Some of the most commonly used types are silicon carbide heating elements, metallic heating elements, and molybdenum disilicide heating elements. For more detailed information on high-temperature materials used in these applications, visit our Understanding Refractories: Essential Materials for High-Temperature Applications page.

In this article, we’ll explore the key applications of kiln heating elements and discuss some of the best products available for each industry.

Applications of Kiln Heating Elements

Kiln heating elements are used across various industries, each requiring specific characteristics. Let’s look at some common applications:

1. Ceramic Industry

In the ceramic industry, kiln heating elements are used to generate the high heat necessary to form and fire clay, porcelain, and other ceramic materials. Silicon carbide heating elements are especially popular in this industry due to their durability and resistance to high temperatures. These elements are commonly used in electric kilns and furnaces to achieve precise temperature control. For more information on the materials that can withstand such high temperatures, visit our Fire Bricks: The Essential Guide for High-Temperature Applications page.

2. Metal Melting

For kilns used in metal melting, heating elements need to withstand extreme temperatures. Silicon carbide heating elements are often chosen for these applications due to their durability and efficiency. They are ideal for melting a range of metals, especially in industries like steel manufacturing and foundries. For more details on equipment used in metal casting and efficient metal melting, check out our article on Aluminum Melting Pot: Essential for Efficient Metal Casting.

3. Glass Industry

Kilns in the glass industry require precise and uniform heating to produce high-quality glass products. Silicon carbide and metallic heating elements are commonly used in glass furnaces because of their ability to distribute heat evenly, ensuring consistent glass formation.

4. Heat Treatment

Kilns in the glass industry require precise and uniform heating to produce high-quality glass products. Silicon carbide and metallic heating elements are commonly used in glass furnaces because of their ability to distribute heat evenly, ensuring consistent glass formation. For a deeper look at the processes and materials used in glass production, read our article on Glass Manufacturing: Key Insights and Techniques for Optimal Performance.

For more information on Silicon Carbide Heating Elements suitable for these applications, visit our Silicon Carbide Heating Elements page.

Types of Kiln Heating Elements

Kiln heating elements come in several designs, each tailored to meet the unique needs of various industrial applications. Some of the most popular types include:

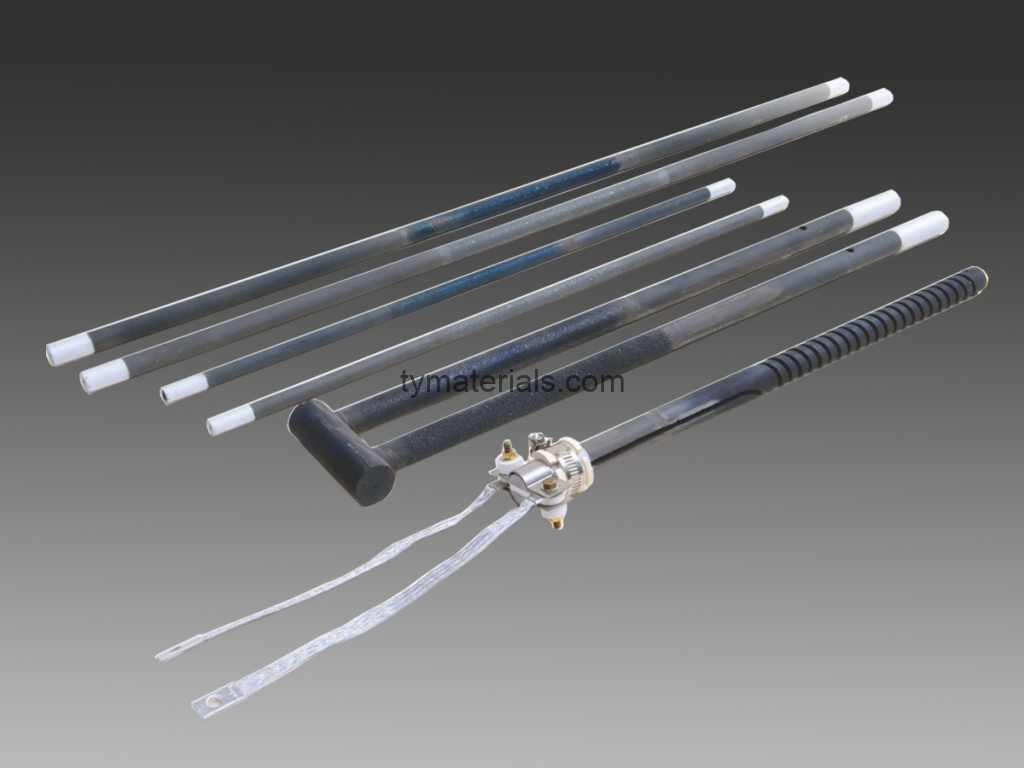

Silicon Carbide Heating Elements

Silicon carbide heating elements are widely used in kilns and furnaces due to their excellent durability and high resistance to extreme temperatures. They are particularly effective in industries like metal melting, ceramic firing, and heat treatment.

We offer several types of silicon carbide heating elements, including:

- Double Spiral Silicon Carbide Heating Element: Ideal for applications requiring even heat distribution.

- Single Spiral Silicon Carbide Heating Element: Suitable for a wide range of industrial heating applications.

- U-Shaped and L-Shaped Silicon Carbide Heating Elements: Perfect for specific kiln and furnace designs.

For a closer look at our Silicon Carbide Heating Elements, click here.

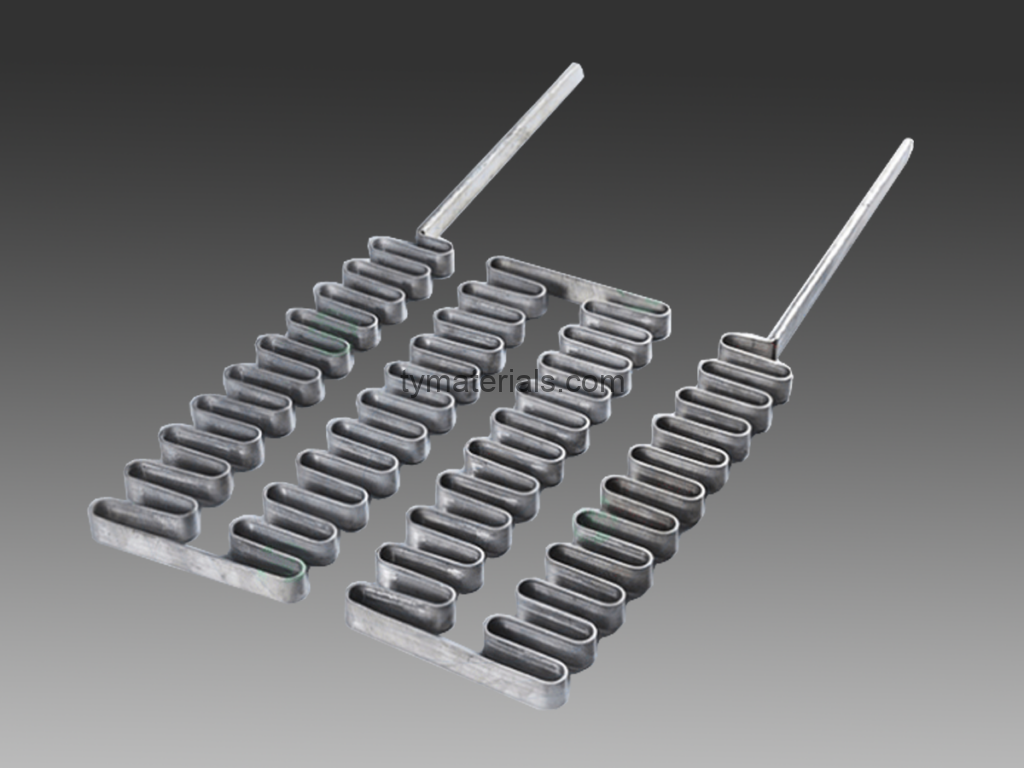

Metallic Heating Elements

Metallic heating elements are often used in applications where the temperatures are not as extreme as those in metal melting or heat treatment. These elements are common in industries such as food processing, laboratory heating, and more.

To discover our full range of Metallic Heating Elements, visit our Metallic Heating Elements page.

Molybdenum Disilicide Heating Elements

Molybdenum disilicide heating elements are designed for ultra-high temperature applications, typically above the capabilities of standard metallic heating elements. They are commonly used in furnaces and kilns for processes such as metal sintering and high-temperature heat treatment.

Explore our Molybdenum Disilicide Heating Element offering here.

Why Choose the Right Kiln Heating Element?

Selecting the appropriate kiln heating element is crucial to ensuring efficiency, safety, and longevity in your industrial processes. Here are some key benefits of using the right heating element:

- Durability: High-quality elements can withstand extreme conditions and reduce the frequency of replacements.

- Energy Efficiency: Properly chosen heating elements reduce energy consumption by ensuring uniform heat distribution.

- Performance Consistency: Reliable elements maintain steady temperatures, which is essential for producing high-quality products.

Learn More About Kiln Heating Elements and Industrial Heating Solutions

To gain further insights into the best kiln heating elements for your application, explore our full range of products. At TY Materials, we specialize in providing high-performance industrial heating elements that meet the needs of various industries worldwide.

Explore Our Industrial Heating Elements

For more information or to discuss your specific heating requirements, don’t hesitate to reach out to us. We can help you choose the best heating elements for your needs.

Have questions? Feel free to contact us, and our team will be happy to assist you.

External Resources

For more industry-specific news and technical articles on kiln heating elements, we recommend checking out Refractories Worldforum, an online resource dedicated to refractories and high-temperature materials. It provides valuable insights into the latest trends in the industry, including innovations in heating technologies. Additionally, for a deeper understanding of how different high-temperature materials play a role in industrial applications, explore our articles on Refractories and Aluminum Melting Pots.