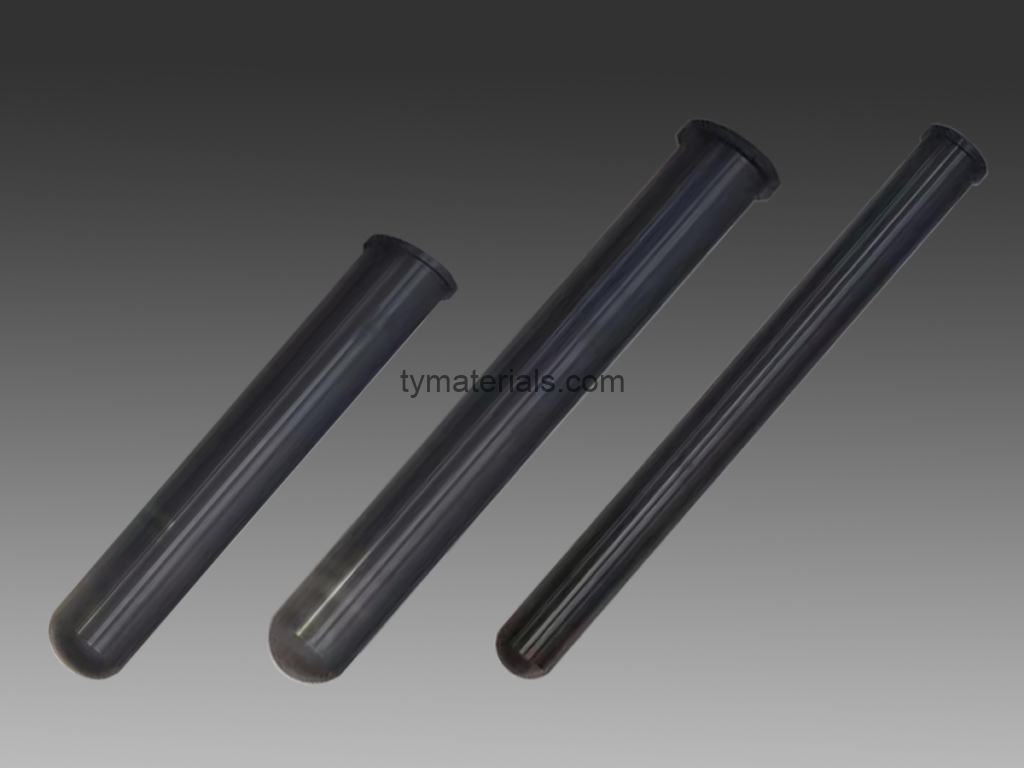

High-Performance Solutions for Accurate Temperature Measurement

Our Thermocouple Protection Tubes are designed to shield thermocouples from extreme industrial environments, ensuring accurate temperature readings, longer service life, and reduced maintenance costs. Available in multiple high-quality ceramic materials, these protection tubes are suitable for a wide range of applications, including industrial kilns, metal processing, and chemical plants.

Key Features

- Exceptional Temperature Resistance: Suitable for temperatures up to 1800°C, depending on the material.

- Material Versatility: Choose from alumina, silicon carbide, and silicon nitride to meet specific application requirements.

- Corrosion and Oxidation Resistance: Performs reliably in chemically aggressive environments.

- Durability: Engineered to withstand mechanical stress and thermal shock.

- Customizable Options: Available in various lengths, diameters, and thicknesses to match your needs.

Applications

Our Thermocouple Protection Tubes are trusted by industries worldwide for their exceptional performance in the following environments:

- Industrial Kilns: Accurate temperature monitoring in high-temperature furnace processes.

- Metal Processing: Protecting thermocouples during the melting and refining of metals.

- Chemical Plants: Reliable temperature control in corrosive or reactive environments.

- Power Plants: Ensuring precision in high-temperature steam monitoring.

- Glass Manufacturing: Supporting thermocouples in high-temperature glass production.

Material Options

We offer a range of materials to suit diverse industrial needs:

- Alumina (Al₂O₃)

- Features: Excellent thermal stability, high corrosion resistance, and cost-effectiveness.

- Best For: Oxidizing environments, glass production, and general-purpose high-temperature applications.

- Silicon Carbide (SiC)

- Features: Superior thermal conductivity, resistance to thermal shock, and exceptional mechanical strength.

- Best For: Fast temperature changes and chemically aggressive environments.

- Silicon Nitride (Si₃N₄)

- Features: Outstanding resistance to rapid temperature fluctuations and chemical corrosion.

- Best For: Aluminum smelting, chemical industries, and demanding thermal processes.

Technical Specifications

| Material | Max Temperature | Applications | Key Benefits |

|---|---|---|---|

| Alumina (Al₂O₃) | Up to 1800°C | General-purpose, oxidizing environments | Cost-effective, corrosion-resistant |

| Silicon Carbide (SiC) | Up to 1600°C | Fast thermal cycling, aggressive environments | High mechanical strength |

| Silicon Nitride (Si₃N₄) | Up to 1400°C | Rapid thermal changes, chemical plants | Anti-corrosion, thermal shock resistant |

Why Choose TY Materials?

- Industry Expertise: Decades of experience in high-temperature solutions.

- Custom Solutions: Tailor-made products to meet your specific requirements.

- Reliable Quality: Trusted by clients across the globe for performance and durability.

FAQs

Q: Can the tubes be customized to fit specific dimensions?

A: Yes, we provide custom lengths, diameters, and wall thicknesses to meet your unique needs.

Q: How do I choose the right material for my application?

A: Consider your operating temperature, chemical environment, and thermal cycling requirements. For more guidance, contact our experts.

Q: Are these tubes compatible with all types of thermocouples?

A: Our tubes are compatible with standard industrial thermocouples, including K, S, and R types.

Call to Action (CTA)

Ready to enhance your temperature measurement systems?

Explore our material options, or request a quote today to find the perfect solution for your application!

Internal Links

- Explore our other high-temperature solutions: Industrial Heating Elements.

- Learn more about High-Temperature Ceramics.

External Links

- For detailed material properties, visit International Electrotechnical Commission (IEC).

- Learn more about silicon carbide in ScienceDirect.