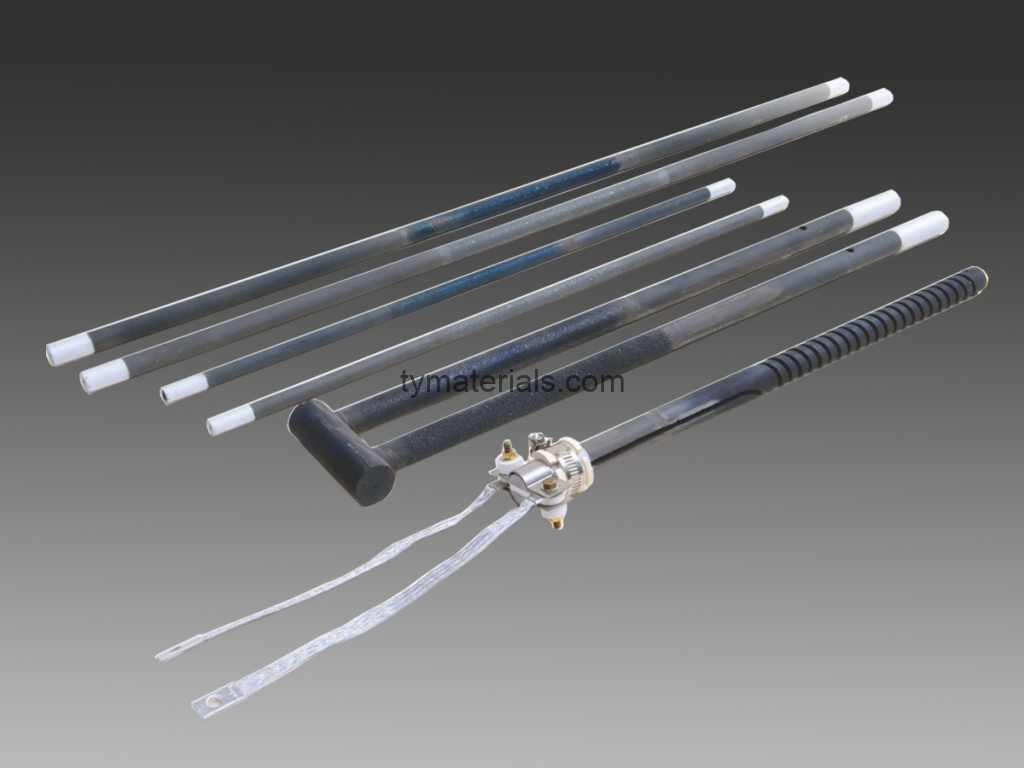

Silicon Carbide Heating Elements: High-Performance Solutions for Industrial Applications

Silicon Carbide Heating Elements (SiC Heating Elements) are vital components for various high-temperature industrial applications. These high-temperature heating elements are known for their outstanding durability and ability to operate in extreme conditions. Whether you need efficient furnace heating elements or reliable resistive heating elements, Silicon Carbide offers excellent performance for industries such as metal processing, ceramics, glass, and more.

Why Choose Silicon Carbide Heating Elements?

Silicon Carbide Resistance Heaters (SiC Resistance Heating Elements) are designed to withstand temperatures up to 1600°C, making them perfect for industrial environments that require stable and high-performance heating. The superior thermal conductivity, resistance to oxidation, and high mechanical strength of these ceramic heating elements ensure a longer lifespan and fewer replacements. Additionally, they are highly energy-efficient, reducing operational costs and enhancing productivity.

Applications of Silicon Carbide Heating Elements

- High-Temperature Metal Processing

Silicon Carbide Heating Elements are frequently used in heat treatment furnaces for metal processing. These electric heating elements are ideal for applications that require precise temperature control in processes like steel hardening, aluminum extrusion, and alloy production. For more details on how these elements contribute to furnace performance, refer to our Heat Treatment Furnace: Enhancing Performance with Industrial Heating Elements article. - Kiln Heating in Ceramics and Glass Manufacturing

In ceramics and glass manufacturing, Silicon Carbide Heating Rods are used to maintain consistent and high temperatures inside kilns. These high-efficiency heating elements are designed to provide uniform heat distribution, crucial for quality production in ceramic glazing or glass melting processes. To explore more about kiln heating systems, visit our guide on Kiln Heating Elements: A Comprehensive Guide for Industrial Applications. - Foundry and Casting Applications

The foundry industry relies on the durable and efficient performance of Silicon Carbide Thermal Elements in the casting of metals. These furnace heating elements help maintain the ideal temperature for molten metal, ensuring consistent quality in casting molds. To learn more about foundry applications, check out our article on Foundry Applications of High-Temperature Materials. - Thermal Insulation for Energy Efficiency

By combining Silicon Carbide Heating Elements with ceramic fiber materials, industries can optimize energy efficiency in heating systems. The combination of thermal heating elements and high-performance insulation reduces heat loss and improves energy conservation. Learn more about energy optimization with ceramic fiber solutions in our article on Thermal Insulation: Optimizing Efficiency with Ceramic Fiber Solutions. - Refractories and High-Temperature Crucibles

SiC Heating Elements are essential for high-temperature crucibles used in metal melting and refining processes. Their exceptional resistance to oxidation and high heat tolerance makes them ideal for long-lasting performance in metalworking environments. Discover more about the role of crucibles in high-temperature applications in our article on Understanding High-Temperature Silicon Carbide Crucibles. - Laboratory and Research Applications

SiC Heating Elements are also commonly used in laboratory applications where high-temperature precision is necessary for experiments, tests, and material analysis. Their resistance to thermal cycling and consistent heating capabilities make them indispensable in scientific research facilities. To learn more about how high-temperature materials are used in labs, explore our High-Temperature Ceramics category.

Why Silicon Carbide Heating Elements are a Smart Investment

- Longevity: The resistance of SiC Heating Rods to thermal shock and oxidation results in a longer service life compared to traditional heating elements.

- Energy Savings: These high-temperature heating elements offer excellent thermal efficiency, reducing energy consumption and lowering operating costs.

- Reliability in Extreme Conditions: Withstanding temperatures above 1600°C, Silicon Carbide Electric Heating Elements are built to perform in some of the most demanding industrial environments.

For a more detailed look at our range of heating solutions, visit our Products page.

Get a Quote

Looking to enhance your industrial heating systems with Silicon Carbide Heating Elements? Request a quote today! Contact us or fill out the form below to get started.

Industry Insights

To stay updated on the latest trends in high-temperature materials, we recommend visiting trusted industry resources like Refractories World Forum, where you can find valuable information on refractory materials and heating solutions.