Heat treatment processes require specialized materials that can withstand extreme temperatures. Refractories are essential in this context, providing the necessary resistance to heat and thermal shock. This process plays a vital role in enhancing the strength, hardness, and durability of materials, making it essential in industries such as manufacturing, aerospace, automotive, and metalworking. In this article, we will explore the importance of heat treatment, the types of equipment involved, and how TY Materials Co., Ltd. provides reliable solutions to support this critical process.

What is Heat Treatment?

Heat treatment refers to a set of controlled thermal processes used to modify the properties of materials. By heating materials to a specific temperature and then cooling them in a specific way, heat treatment can improve material hardness, toughness, flexibility, or wear resistance. Common heat treatment processes include:

- Annealing: Heating a material to a high temperature and then slowly cooling it to soften it and improve its ductility.

- Quenching: Rapidly cooling a material, usually by submerging it in water or oil, to increase hardness.

- Tempering: Reheating quenched material to a lower temperature to reduce brittleness.

- Carburizing: Adding carbon to the surface of steel to harden it.

The Role of Industrial Heating Elements in Heat Treatment

Some heat treatment furnaces, especially those used for metalworking, share common characteristics with aluminum melting pots, which are designed to provide efficient and controlled heating for molten metals. The use of industrial heating elements in heat treatment is closely tied to resistance heating, a technology that converts electrical energy into heat. This method is ideal for achieving precise temperature control in furnaces.

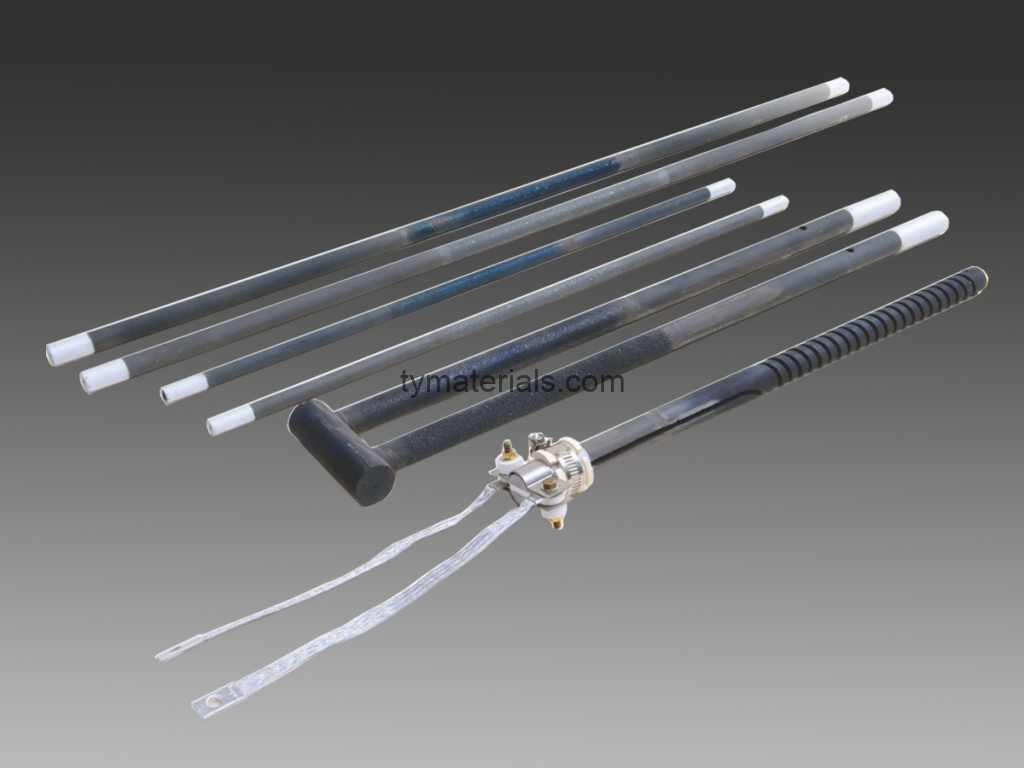

Silicon Carbide Heating Elements

Silicon carbide heating elements are widely used in high-temperature applications, including heat treatment furnaces. These elements provide superior thermal stability and can reach temperatures of up to 1,650°C. Our range of Silicon Carbide Heating Elements includes various shapes such as double spiral, U-shaped, and L-shaped, ensuring we meet the specific requirements of your heat treatment processes.

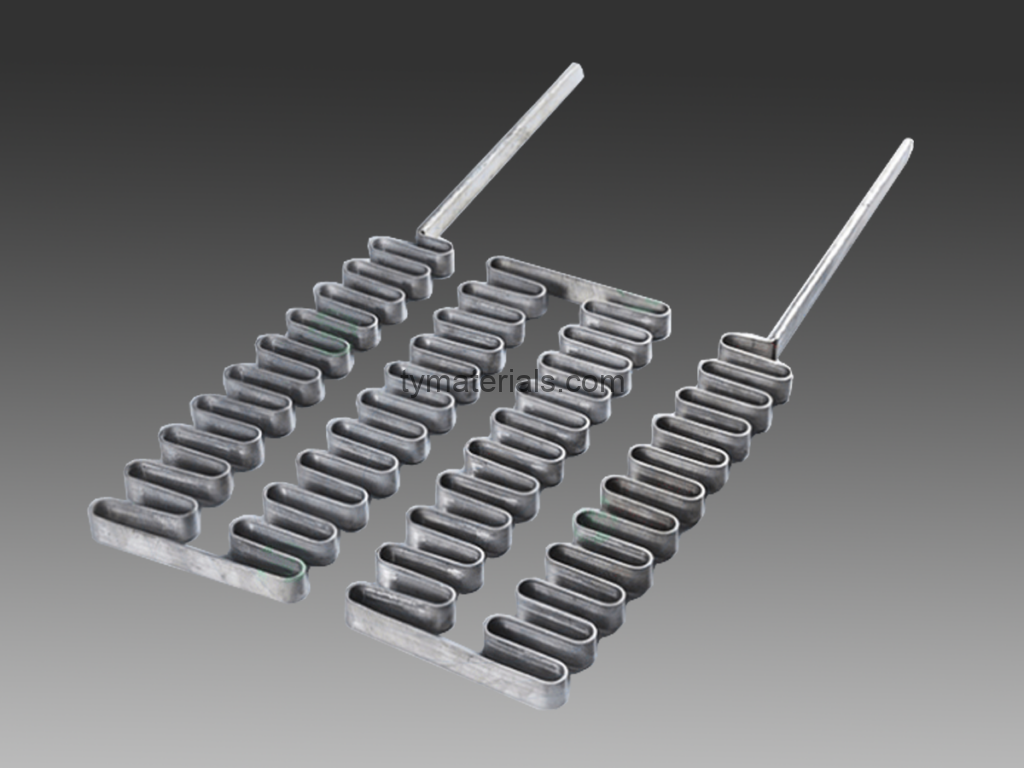

Metallic Heating Elements

Metallic heating elements are another key solution for heat treatment applications. They are typically used in lower-temperature applications but still offer excellent thermal conductivity. If you are looking for cost-effective heating solutions that offer reliability and durability, our Metallic Heating Elements are an ideal choice for many industrial heating processes.

High-Temperature Ceramics for Heat Treatment

In addition to heating elements, high-temperature ceramics are indispensable in heat treatment processes. These materials help maintain the integrity and efficiency of the heating equipment and play a crucial role in the insulation and containment of heat. Products such as Silicon Carbide Radiant Tubes and Thermocouple Protection Tubes are essential for ensuring that heat is applied efficiently and consistently during the treatment process.

For example, Silicon Carbide Radiant Tubes are ideal for use in high-temperature furnaces, providing both insulation and a medium for radiant heat transfer. These tubes are designed to withstand high thermal stresses, making them an excellent choice for industries where heat treatment is a critical component of the production process.

Ceramic Fiber for Thermal Insulation

In addition to heating elements and high-temperature ceramics, to ensure efficient heat retention, ceramic fiber insulation is used to line the furnace, preventing heat loss and improving energy efficiency.

For example, our Ceramic Fiber Blanket offers high thermal resistance and can be used to insulate the furnace, preventing heat from dissipating during the heat treatment process. This helps improve energy efficiency and ensures that the desired material properties are achieved.

The Importance of Quality Heat Treatment Equipment

Using high-quality heating elements and ceramics ensures that the heat treatment process is carried out effectively, reducing the likelihood of material defects and improving the overall quality of the finished product. When choosing heat treatment equipment, it is crucial to consider not only the performance but also the durability and reliability of the components.

At TY Materials Co., Ltd., we pride ourselves on offering top-tier industrial heating elements, high-temperature ceramics, and ceramic fiber products that can withstand the demands of high-temperature processes. Whether you are looking for Molybdenum Disilicide Heating Elements or Ceramic Fiber Wool, we have a wide selection to meet your specific heat treatment needs.

Learn More About Heat Treatment and Industry Trends

For more insights into the role of heat treatment in industrial processes, we recommend visiting industry-leading sources such as Refractories Worldforum. This platform provides valuable resources on the latest trends, technologies, and research related to heat treatment and refractory materials.

Get in Touch for Custom Heat Treatment Solutions

If you’re looking for customized solutions for your heat treatment processes, we’re here to help! At TY Materials Co., Ltd., we understand the importance of quality materials in the heat treatment process. Contact us today to discuss your needs and get a personalized quote.

Contact Us

Have questions or need further information on our products? Feel free to reach out to us through our Contact Us page, and one of our team members will be happy to assist you.

Conclusion

Heat treatment is a vital part of many industrial processes, and the quality of the equipment used can significantly impact the effectiveness of the treatment. By choosing high-performance heating elements, ceramics, and insulation materials from TY Materials Co., Ltd., you can ensure that your heat treatment processes are both efficient and reliable. Whether you need Silicon Carbide Heating Elements or Ceramic Fiber Modules, we are committed to providing the highest quality products to meet your needs.

Get a Quote or Contact Us for More Information

For more details or to get a quote tailored to your requirements, please don’t hesitate to contact us today!